For many years, a&g is a competent partner in regard to development, manufacturing and application of hysteresis brakes and clutches.

Hysteresis Brakes

Our hysteresis brakes are composed of an armature and a brake magnet and offer brake values between 0.4 and 39 Nm. Hysteresis brakes are available as bearing version and non-bearing version. These brakes are suitable for applications as for instance holding brakes or slip operation.

Hysteresis Clutches

Our hysteresis clutches are composed of an armature, rotor and a clutch magnet and come in torque values between 0.4 and 39 Nm. Maximum slip power values up to 1 000 W are available. The special feature of the hysteresis clutches of a&g is their continuous transition from synchronous to slip operation mode. Manufacturing tolerances range between ±10% as for the hyster – esis brakes. Customised pairs with lower and corresponding tolerances are available, too.

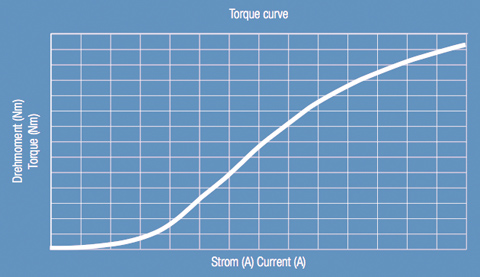

Significant features of the hysteresis brakes and clutches from a&g are their high precision, absolute repeatablitiy and their wearless character, which is the main advantage of the hysteresis products. Tensile forces and torques may be regulated continuously. Corresponding to our devices we provide a reasonably priced control unit (RHE).

Functional principle

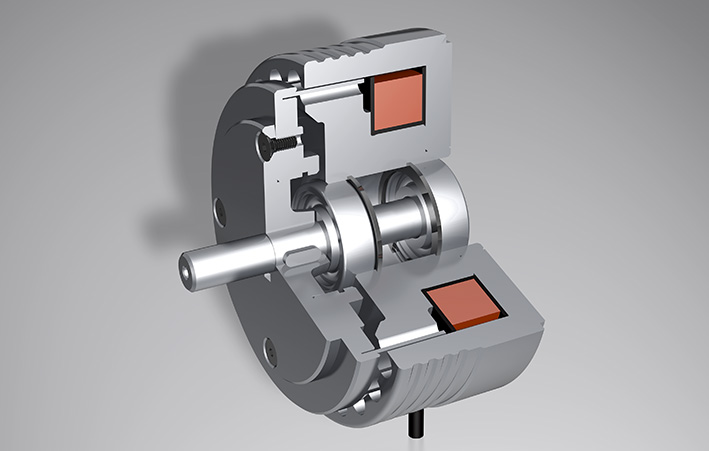

The most important components of hysteresis brakes and clutches are their rotor and pole structure. This pole structure is composed of an external body and an excitation coil. These pieces constitute the static or the actuated part of the brakes and clutches. The result is a braking and coupling force caused by magnetic interaction. Moreover, the pole structure consists of an internal and external pole structure, which is separated by an air gap.

The rotor constitutes the major difference between hysteresis brakes and clutches: Regarding hysteresis brakes it is the moving part, whereas it is the output for hysteresis clutches.

Typical applications

Hysteresis technology is usually employed for winding processes of yarn, textile, cable, fabrics, paper, plastic layers, etc. Thus the brakes and clutches of a&g are used in mainly all high technology applications of winding and stranding industry.

As a result of their high repeatability, their wear- and maintenance free feature, these devices are also used in test bench technology.